Quality Control

Quality Control

|

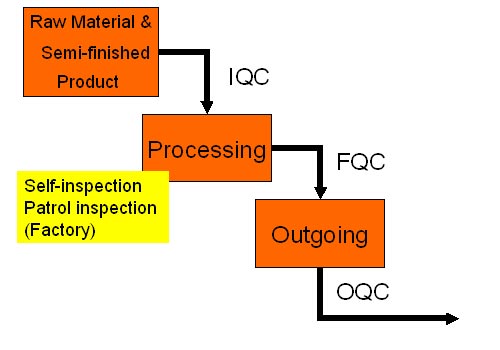

1.IQC

Main Responsibility¡G - Spot-check the material dimension, ingredients and etc¡K based on standard inspection procedure in order to effectively reduce inferior parts into the manufacturing process |

|

a. Dimension Measurement

| - Utilizing Misutoyo caliper to measure the material including case, actuator, cover and so on. - Misutoyo profile projector is for precision measurement |

|

b. Electro-plating coating thickness test

| Fischer X-Ray coating thickness gauge is to test the material and thickness of electro-plate coating. |  |

2. IPQC

Main Responsibility¡G Implement self-inspection and patrol inspection based on the standard operation procedure in order to prevent substandard parts from going to the next work station. |

|

a. Mold / Tool Adjustment

| The tools are regularly handed to our engineering division for precision measurement in order to avoid any accuracy alteration caused during the production process. |  |

3. FQC

Main Responsibility: Implement the inspection on the quality of finished products by using testing equipment in order to eliminate inferior products not judged by the outer appearance or caused by electric characteristic. |

|

a. Function Test and Contact Resistance Test

| - Utilizing specialized testing tool to test if the function is normal. - Utilizing digital miliohmmeter & comparator to test the contact resistance in order to effectively eliminate inferior products. |

|

4. OQC

| Reponsibility¡G Spot-check each lot of products for quality before final shipment. We also have a destructive test on the operating life in order to minimize inferior products to be shipped to customers. |

|

a. Waterproof Test

| For sealed switches, we have bubble test by utilizing fluorocarbon 3M FC-40. |  |

b. Feeling Test

| Utilizing AICOH testing equipment to make feeling test for pushbutton switches . |  |

c. Mechanical Life & Electrical Life Test

| Utilizing endurance testing machine to test the operating life in rated current load. |  |

d. Environment Test

| Utilizing imported environment testing machine to test the resistance low temperature, resistance high temperature and resistance humidity. |  |

e. Insulation Resistance Test

| GW Instek multi-function testing facilities is to test the insulation resistance and dielectric strength. |  |